Foundry

Our advanced manufacturing units ensure consistent quality and high-volume capability.

Foundry

production Capabilities

At LADA Foundry, our production capability is driven by advanced technology, precision processes, and a skilled workforce. With state-of-the-art molding systems, modern melting facilities, and strict quality controls, we ensure every SG and ductile iron casting meets the highest standards. Our efficient infrastructure enables us to handle both large-scale and customized requirements, delivering reliable, durable, and high-performance products that reflect our commitment to excellence.

MOLDING SHOP FOR ARPA LINE

- DISA Simultaneous Jolt Squeeze Molding Machines with Semi-Automatic Mold Handling System.

- Production Rate of ARPA 450 :

Molding Box Size : 510 x 560 x 150 : 50 Molds/Hour.

- Production Rate of ARPA 450 :

Molding Box Size : 610 x 710 x 200 : 40 Molds/Hour.

SAND PLANT FOR ARPA LINE

- Fully Automated Sand Plant Capacity: 25 MT/Hour.

- Automatic Sand Controller System, Hydraulic Pusher, Hydraulic Punch-out, Metallic Conveyor.

- Sand Cooler Capacity: 25 MT/Hour.

- Sand Mixer Capacity : 1 MT/Cycle.

MOLDING SHOP HPML

- HPML SINTO FBO III (S) – 510 x 660 x 200.

- HPML Production Rate – 133 Molds / Hour.

SAND PLANT FOR HPML

- Fully Automated Sand Plant Capacity : 30 MT/Hour.

- Automatic Sand Controller System,

Casting Cooling conveyor.

- Sand Cooler Capacity : 30 MT/Hour.

- Sand Mixer Capacity : 1 MT/Cycle.

MELTING SHOP FOR ARPA LINE

- Medium Frequency Induction Furnace

(Inductotherm Make)

- 750 Kg. – 750 KW.:- 02 Nos.

- 1000 Kg. – 1000 KW.:- 01 Nos.

- Melting Capacity: 60 MT/Day.

- 2 Digital Temperature Contact less (Infrared) Pyrometers.

- 2 Digital Temperature Contact type Pyrometers.

- 2 Digital Platforms Weighing Balance of 1000 kg.

- 2 Wireless Digital Cranes Weighing Balance of 5 MT.

- 3 SG Iron Treatment Ladles of 1000 kg.

- 8 Pouring Ladles of 500 kg each.

- 2 Overhead Cranes of 5 MT each.

- Magnesium treatment by Sandwitch method.

MELTING SHOP FOR HPML

- Medium Frequency Induction Furnace 500 Kg.-4 Nos (Quadra track ) : 1750 KW.

- Melting Capacity: 50 MT/Day.

- Auto Pour – 500 kg./Batch

- 2 Digital Temperature Contact type Pyrometers.

- 1 Digital Temperature Contact less Pyrometer.

- 4 Digital Platforms Weighing Balance of 500 kg.

- 2 Wireless Digital Weighing Balance of 5 MT.

- 3 SG Iron Treatment Ladles of 500 kg.

- 3 Pouring Ladles of 500 kg each.

- 3 Overhead Cranes of 5 MT each.

- Magnesium treatment by Sandwitch method.

- Cored wire Magnesium Treatment.

AUTO MG CORED WIRE FEEDER SYSTEM

- Capacity – 500 Kg / Batch.

- Mg treatment controlled automatic with base metal Sulfur %, metal weight and metal temperature.

AUTO POURING SYSTEM

- Auto Pouring capacity – 500 Kg/Batch (Every 15 Min).

- Auto Mould Inoculation system.

- In Built with Infrared Pyrometer (Controls pouring with minimum and maximum Temperature range of metal).

- In Built Mg fading time control system.

- In Built HMI to monitor pouring time and pouring temperature per mould.

IN HOUSE CORE MAKING FACILITY

- Cold box core making Machines 300 mm X 300 mm X 300 mm : (Compax Make).

- Core making capacity :- 60 gms To 5 Kg.

- Cold box core making Machines 400 mm X 600 mm X 500 mm : (Advik Make).

- Core making capacity :- 1 Kg To 10 Kg.

- Cold box core making Machines 600 mm X 600 mm X 800 mm : (Galaxy Make).

- Core making capacity :- 5Kg To 20 Kg.

FETTLING SHOP FOR ARPA LINE

- 2 Hanger Type Shot Blasting Machines.

Capacity: 500 Kg. & 1000 Kg.

- 2 Tumblast Type Shot Blasting Machines.

Capacity: 300 kg. – 750 Kg.

- Hydraulic wedge Cutter 4 Nos.

- The sundry equipment like chippers, angle grinders, straight grinders, pedestal grinders.

- The dimensional inspection equipment like surface plate 1000 mm x 1000 mm, vernier calipers, digital height gauge 400 mm, Digital Pistol Caliper etc.

FETTLING SHOP FOR HPML LINE

- One Hanger type shot blasting Capacity – 1000 kg

- One Tumblast – Capacity 750 kg.

- Hydraulic Wedge Cutter – 4 Nos.

- The sundry equipment like chippers, angle grinders, straight grinders, pedestal grinders.

- The dimensional inspection equipment like surface plate 1000 mm x 1000 mm, vernier calipers, digital height gauge 400mm, Digital Pistol Caliper.

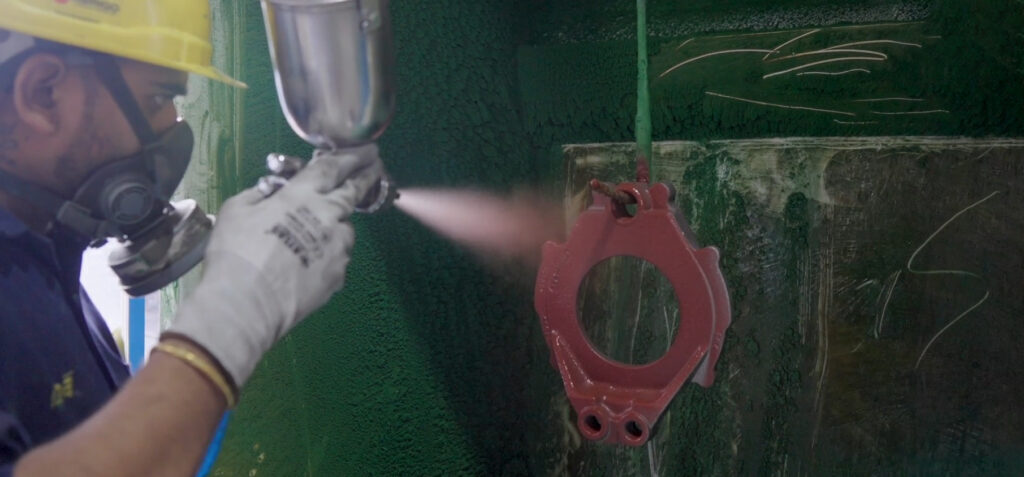

CASTING PAINTING FACILITY

- 5 Nos. of Spray Painting Booths.

- 1 No. of Spray Painting Booth with overhead drag chain and Paint drying oven.

- 8 Nos. Paint Deeping stations.